Principle:

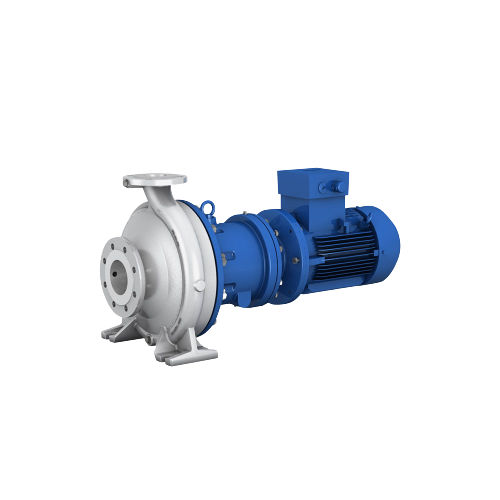

The centrifugal pump is driven by a pair of magnets, which are incorporated in the impeller and motor shaft, respectively. The sealess pump structure elliminates shaft seals, such as conventional mechanical seals, because the pump chamber is shielded by the casing and the impeller is operated by a magnet. The combined coupling torque of the drive magnet and impeller magnet drives sufficient driving power against the motor torque.

Range:

- Flow Rate : max. 100m3/h.

- Delivery Head : max. 100 metre.

- Pressure Rating : Class 150.

- Temperatures : -35°C to +250°C.

- Kinematic viscosities : 0.5 to 350 mm2/s.

Material of construction:

Stainless steel SS 316, SS 316L, SS 304, SS 304L Other materials duplex alloys , nickel-base alloys (e.g. Hastelloy®),

Features:

- Single Stage, Horizontal Centrifugal Pump.

- Hydraulic Performance and Dimensions according to DIN EN ISO 2858.

- Technical design based on DIN EN ISO 15783.

- Permanent Magnet Drive.

- Maintenance Free.

- Separation of Liquid Chamber to Atmosphere by Means of Isolation Shell.

- Slipless Power Transfer.

- Materials : Steel, Stainless Steel, Nickel Based Materials.

- Close Coupled Block Design.

- Hydraulically balanced impeller for minimum bearing loads.

- Product-Lubricated Journal Bearings; made of Silicon Carbide (SSiC) or Customized Materials.