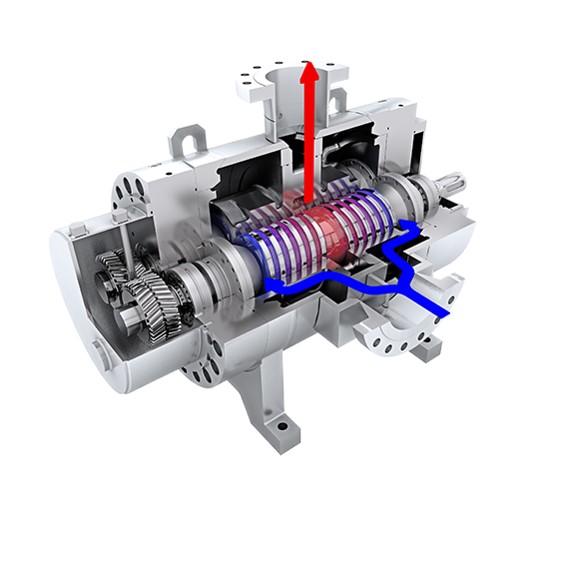

Working principles:

These pumps are self-priming, double-ended positive displacement pumps with external timing gears and bearings. As the screws rotate, cavities are formed between the individual screws. These hold a given volume of fluid, moving it axially as the screws rotate. The portion of the fluid that entered the pump was diverted to the left or right is then moved forward from left to center and from right to the center. At the center, the two flow paths rejoin and leave the pump through the discharge flange.

Ranges:

- Capacity: 20 to 500 m3/hr.

- Pressure: Normal 16 bar/ 24bar, with special designs up to 50 bar.

- Viscosity: 1 cSt to 50,000 cSt or more.

- Temperature: -30 to +350°C.

Material of construction:

- Body – CI,CS,SS, Bronze.

- Rotor –CS,SS, Bronze.

- Liner-CI,CS,SS, Bronze.

Features:

| Positive clearance between rotors | Insensitive to varying viscosities |

| No metal to metal contact between rotors | Long maintenance free service |

| Dry running capability | Lowest NPSHR |

| Negligible wear over years | Shaft sealing at suction pressures |

| Axial smooth steady flow | Axial thrusts completely eliminated |

| High speed running | Interchangeable liner |

| Pulsation free output | Adaptability of various MOC |

| Negligible vibrations |

Typical Applications:

- Loading / unloading of fuel oil and other products from: Railway wagon rakes, Truck tankers, Barges, Ships and Tankers.

- Bulk cargo handling.

- Lubrication, circulation and cooling.

- Process pumping of high viscous products, bitumen, molasses, soap and similar products.

- Long distance pipeline pumping of viscous products.