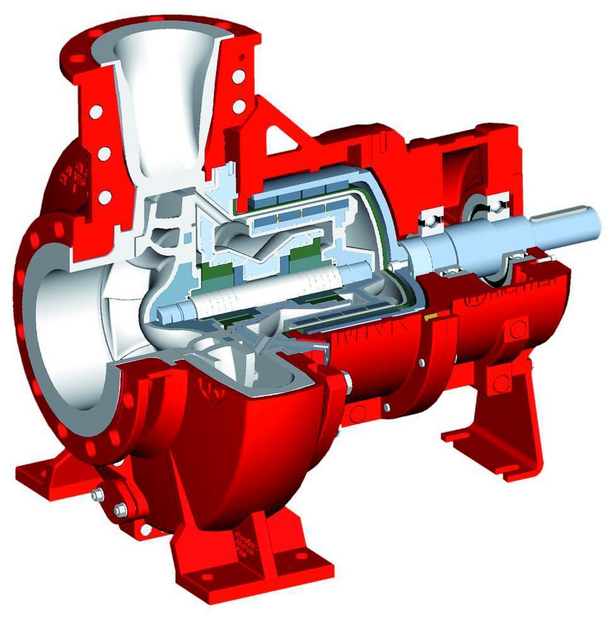

Backed by a team of experienced professionals, we are supplying an extensive array of chemical process pumps. In order to fabricate these pumps, our vendors utilize premium-quality raw materials and cutting-edge technology in compliance with international standards. These pumps have a special stable-bearing pedestal that assures smooth running even during difficult applications, thus receiving optimum pre-conditions for the mechanical shaft seal's long life.

Range:

- Flow rate up to 300 M/Hr.

- Head up to 90 mts liquid column.

- Temperature range from 0 - to 80 Deg can be handled by PP MOC.

- Temperature range from 0 - to 130 Deg can be handled by PVDF, FEP, and PFA MOC.

Material of construction:

- PP

- PVDF

- PFA

- FEP

Features:

- Durability.

- High in performance.

- Less maintenance.

- Tried and tested chemical process pump design for rough conditions.

- Thick-walled vacuum-proof plastic housing in one piece.

- Plastic housing encapsulated in tough material.

- Pipeline processes are absorbed by the metal armour.

- Ideal for high system pressures.

- Flanges with through holes meeting the requirements of the chemical industries.

- Semi-open PVDF impellers are reinforced by large metal inserts.

- Smooth running and durability of the mechanical seal.

- Modular system ensuring cost effective spare parts stocking.

- External corrosion protection of pump and base plate by an epoxy paint.

Applications:

- Scrubbing of corrosive gases like Cl2, F2, I2, SO2, SO3, CO3, NH3.

- Effluent treatment, water treatment.

- Pickling in steel rolling mills.

- Drugs & pharmaceutical industries.

- Filter press for dyes.

- Electroplating, descaling.

- Chemical, fertilizers, paper and pulp plant.

- Thermal and automic power plant.

- Rayon and staple fibre plant, copper zinc smelters.

- Caustic soda plant, TiO2 plant, steel plants.

© 2025 SMIV - All Rights Reserved.